I'll be rebuilding the 1275 engine for my resto, and thought that if I cannot have Doc or GR or miniman Matt or any of you other gurus looking over my shoulder in the garage, then maybe I can have them look over my shoulder in cyberspace.

I've built a few engines up now, but always in a very simple manner, I've trusted that the parts are good, and that they will fit sufficiently enough to perform well. That's what I know as I am certainly no engine fitter/ machinist by trade. It's worked well for me over the years, but there is a difference. Anyone can bake a crappy packet mix cake, but it takes a little skill to make a pavlova.

Maybe if you would like to do your own, then this may be a voyeuristic way of having a go. Then maybe I will take requests and wear a little French maids outfits whilst I spank the block with a feather...................no way you sickos~!:evil:

Anyway, the background and the materials we have to work with:

This is a Mk2 Cooper S block. Not your usual mini engine, but not so very different from any other mini engine for everything except sizes. It was once a pretty sad looking block, but it was complete. When it was pulled down, number two piston had a shattered crown from detonation. This I believe is the reason it was put aside by the previous owner.

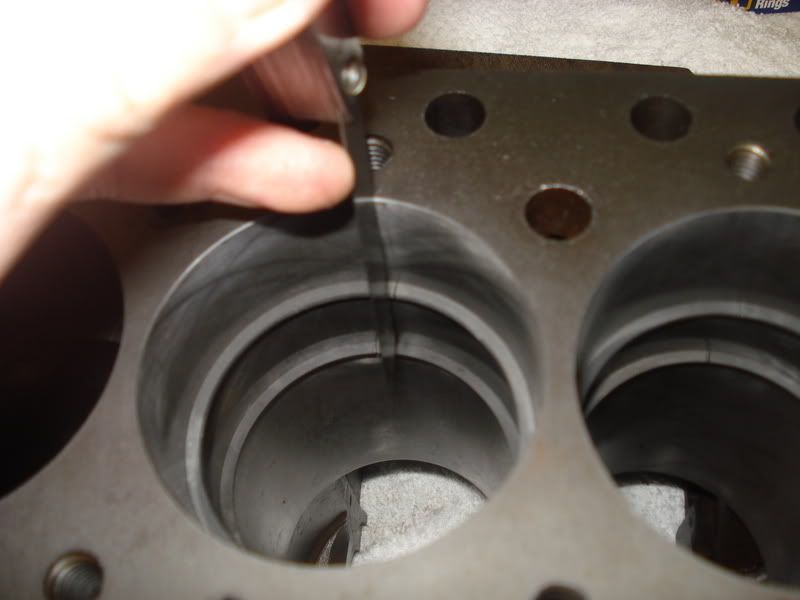

The block was hot tanked (here at home) blasted with high pressure detergent and then tanked again to remove all the grunge, slime and paint from the engine and it's galleries. All plugs were removed to do this, and have been replaced with new plugs after machining. The top of the block was machined flat, the bores re-bored to the next oversize and honed, and the crank crack tested, inspected and linished. The crank sizes on the main bearing and the big end journals are both currently at 10 thou of an inch under their original size.

Pistons were installed onto the con rods after they too were inspected, straightened and cleaned. The rings await installation which will be the first step. The bench is cleaned and set aside for the duration of the engine build (at least until the short block is completed).