I had some free time a few weeks back and decided to have a closer look at my old 998 engine. It was running when I removed it in 2019 (although had a few issues) and I thought it'd be good to check it all out, replace some gaskets and have it complete in case I ever need a spare engine (or lend to someone else). I also just felt like digging into an engine and poking around

A bit of history - my grandpa had installed this engine sometime in the late 80's to early 90's. I'd originally been told it was an 1100 engine but the stamped number is a 9YTaH from a 998 deluxe (I actually haven't measured the stroke yet). It has a 22G68 3 synchro gearbox, remote shifter and apart from the alternator and distributor it was all 1960's gear. I don't know exactly what was kept from the original 850 and what came with the donor 998 - was it just a 998 engine block, or was it also the gearbox? The HS2 carb was on the original cast manifold, and it had the 850 tag on the float bowl and EB needle. Unfortunately my grandpa isn't around anymore and I should have asked him more questions at the time

From 2013 to 2019 I did lots of miles, went to Bathurst in 2016 and did three Rylstone Classic trips. I replaced the rubber universal joints with the QL5000 type joints. The QL5000 joints failed about a year later and then I swapped it to Hardy Spicer couplings. I also added a Minispares "Stage 1 Kit" with a larger HS4 carb, and then a few years later swapped to a Dellorto DHLA40

In 2019 I'd finished building my 1100 engine, so the day after I got back from Rylstone 2019 out came the engine.

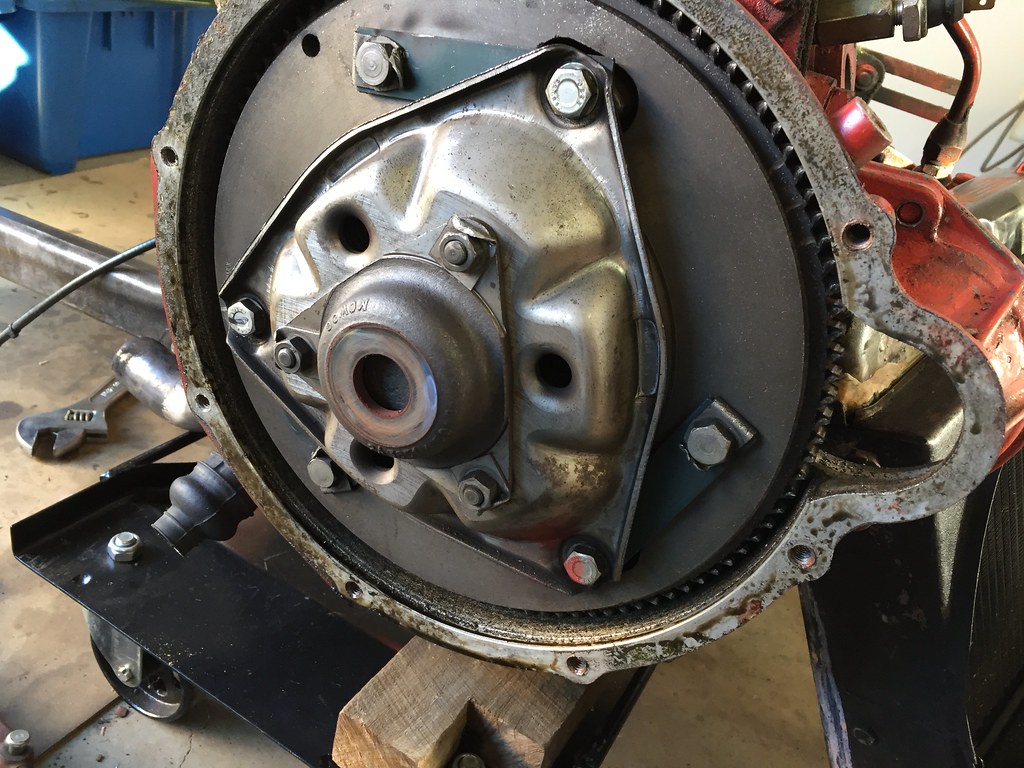

At that time I found mystery number 1 - the clutch was the old spring diaphragm and not the later type. I haven't checked if these were installed to the 998 Deluxe or if this was carried over from the 850

So now it's been sitting in a box untouched since 2019 when it was removed from the car. I took a few parts off it for the 1100 engine like the water pump, oil feed pipe etc. I'd also removed the Hardy Spicer diff and sold it on.

I started the strip down and the first thing I noticed was the rocker posts are the old alloy type, not the cast iron

With the head off there was one of the nice ACL monotorque head gaskets

Another surprise - it has 040 oversize pistons already

The head had a bit of crusty deposits on it

The cam followers were the type with drain holes and had no pitting or wear I could feel.

I did a clean up and found my workbench.

The head chambers partway through cleaning - they weren't too bad. The intake seats were pretty clean but the exhausts will need a bit of lapping. Getting the valve lapping tool to stick to the tiny exhaust valves has been a challenge!

Working on this exact head was the first car related thing I ever helped with. My dad didn't do much mechanical work (he liked working with timber), and at some point in the 90's my grandpa had this 998 head refurbed and converted for unleaded. I helped him to reinstall the valve springs and retainers - we'd gone to one of his friend's houses and borrowed a spring compressor that was way too big, so a socket was held between the valve and compressor to get the height right.

The good points:

It was reliable

Smooth

Unleaded head

The bad points:

2nd gear synchro was gone

It would occasionally pop out of 1st and 4th gears under load

Low oil pressure at idle - the light would come on if the idle was under 1000rpm

Valve springs topped out at 5500rpm

The plan:

Replace all the gaskets

Lap the valves and replace the stem seals

Reassemble the head back exactly how it was. The valve springs did limit the RPM, but this probably means it's kinder on the valve train

Replace the 2nd gear synchro ring. I have no idea what kind of gears are in the gearbox yet

Put in a pot joint diff to suit the mini now

Investigate the low oil pressure

Overall just pull it all apart, replace some wear items and put it back together as it was. It worked well enough to be kept for a spare

I have got a spare magic wand diff housing, so if it fits OK I might consider swapping this to magic wand so it's an easy bolt in to my mini (I swapped from remote to magic wand with the 1100). However I do miss the remote shift so that's a decision to make later.