As I was going through this process at the weekend, I thought I'd take a few pictures, I know a lot of you will be familiar with this, but hopefully for those who have not seen this before it will be of assistance

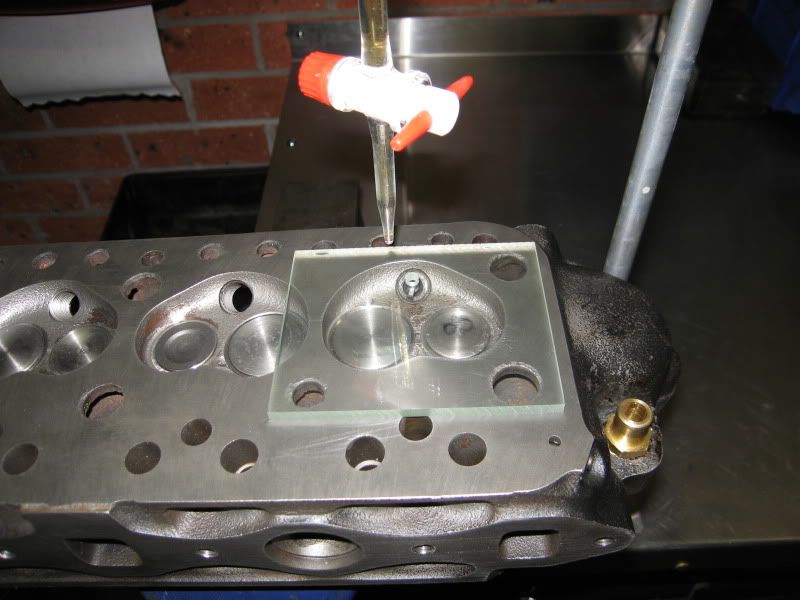

Firstly I made a plate from a free offcut of 4mm perspex, then drilled a 3mm hole:

This is how it will fit and seal the head:

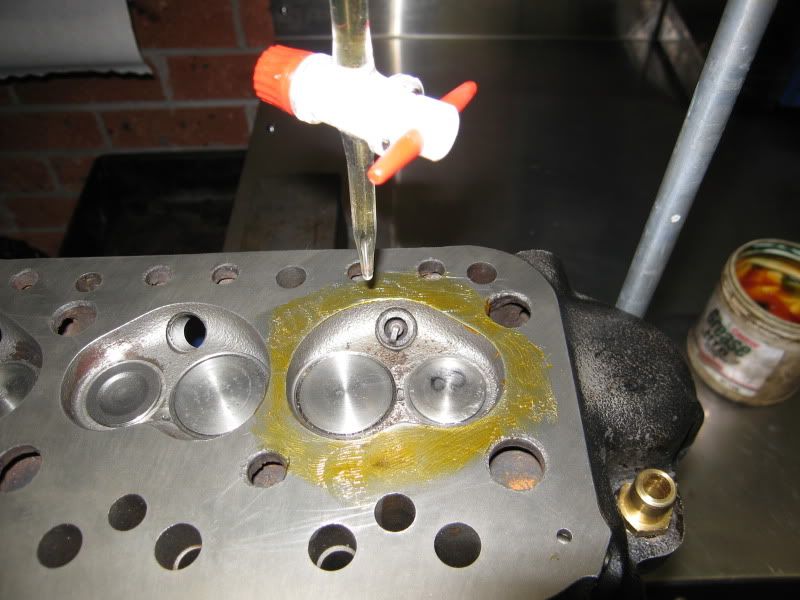

Seal the face with a little grease:

Then run in liquid (I used kero) from the burette to measure ther volume:

This being a 12G295 head, I added 5ml (CC) to start with, then measured:

So 5 plus 22ml is a total of 27.0 ml for this head which has had a clean up skim (12G295 usually 28.3 ish..)

Final picture of full set up:

Burettes are available from Lab supply places.

I also did the same excersise on the block with the piston at tdc, the dished piston and area above the piston yielded 9.5ml, so total volume on this 0.060" over 1098 is 36.5ml, plus say 1.7ml for gasket (tot 38.2)...

So, question time! what's the current compression ratio!