mini-dunger wrote:

Has anyone got that diagram of the oil flow path in a. A-series? The engine had something go through it as the bearings had scuff marks in them.

like this?

| ausmini https://ausmini.com/forums/ |

|

| Camshaft and lifter failure https://ausmini.com/forums/viewtopic.php?f=2&t=98910 |

Page 1 of 4 |

| Author: | mini-dunger [ Thu Aug 01, 2019 6:01 pm ] |

| Post subject: | Camshaft and lifter failure |

Hey all This is the second engine I have built that has had knackered lifters and worn cam lobes.. The only thing common in both engines is the rocker gear. Both engines had maybe 5k on them. Any ideas? Pic included |

|

| Author: | John Sneddon [ Thu Aug 01, 2019 6:49 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

Are you using a good quality engine oil with zinc? My engine builder advised me that if you do not the problem you are experiencing will be present, usually sooner than later. He showed me some followers from an engine which had suffered the same fate. |

|

| Author: | drmini in aust [ Thu Aug 01, 2019 7:20 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

Were the lifters radius ground? All are supposed to be, but the factory in India that makes most of them including Isky style ones can't seem to comply. I bought a set of Isky ones recently that weren't even flat, they were concave! The combination of radius grinding and a slight angle across the lobe makes them spin to minimise wear. The bloke who grinds the cams I use, now always radius grinds new lifters. |

|

| Author: | IndigoBlueCooperS [ Thu Aug 01, 2019 8:35 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

Was this a reground cam? Does the grind go through any hardened surface on the original cam? And if so, was it re-hardened or surface treated? I guess this would be more applicable on a cam with a rapid lift profile. |

|

| Author: | mini-dunger [ Thu Aug 01, 2019 8:51 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

It’s an Re13t so it had the proper treatment. This engine spat a gudgeon so it was making metal. Probably had something to do with it |

|

| Author: | mini-dunger [ Thu Aug 01, 2019 8:54 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

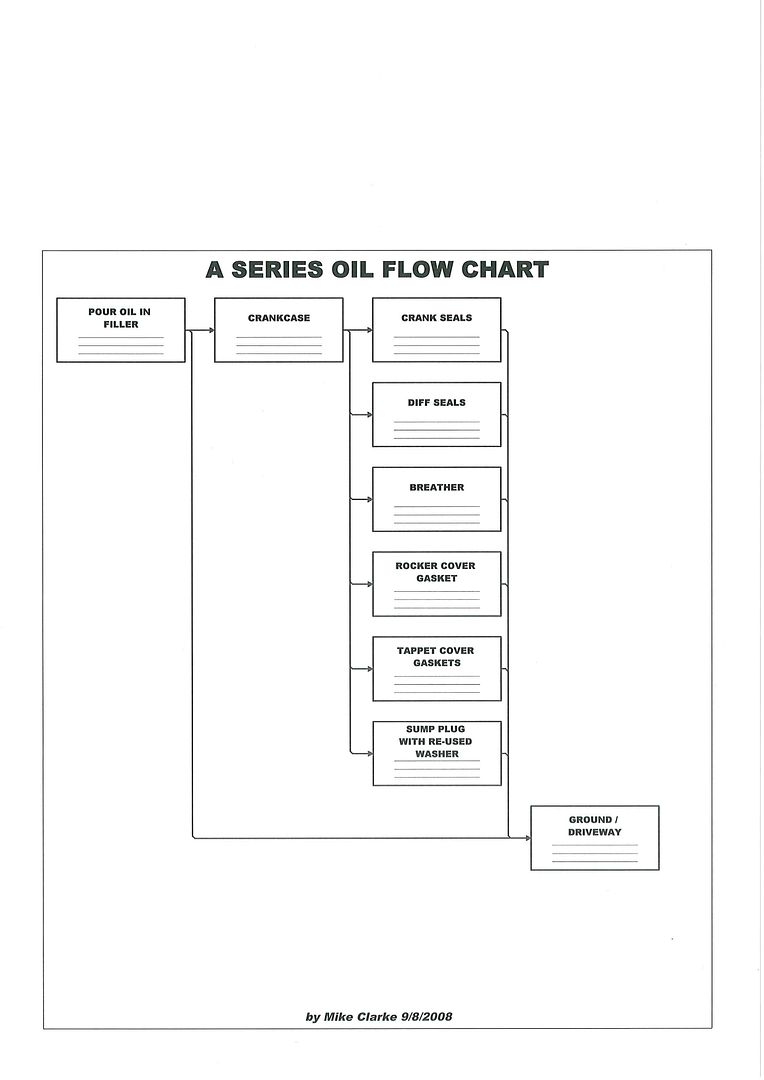

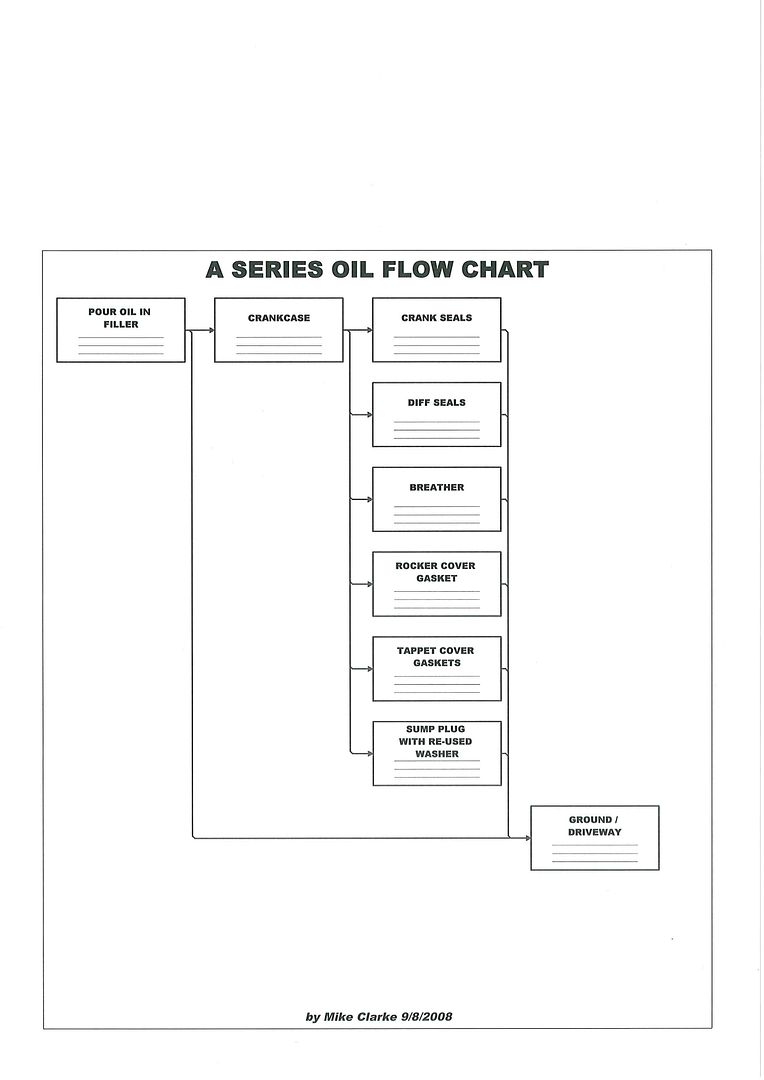

Has anyone got that diagram of the oil flow path in a. A-series? The engine had something go through it as the bearings had scuff marks in them. |

|

| Author: | mini-dunger [ Thu Aug 01, 2019 10:18 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

By proper treatment I’m referring to the radius on the lifters |

|

| Author: | Pumba [ Fri Aug 02, 2019 3:35 am ] |

| Post subject: | Re: Camshaft and lifter failure |

mini-dunger wrote: Has anyone got that diagram of the oil flow path in a. A-series? The engine had something go through it as the bearings had scuff marks in them. Only way that happens is if the oil galleries were not thoroughly cleaned before the rebuild (all contaminated engine oil from the gearbox first goes through the oil pump then the oil oil filter before getting to the bearings). Also on the initial start up did you run the engine at 2500 rpm for 20 minutes to run the cam followers in? |

|

| Author: | mini-dunger [ Fri Aug 02, 2019 8:38 am ] |

| Post subject: | Re: Camshaft and lifter failure |

Yeah mate. I ran it all in properly. And had the engine hot tanked. I’m starting to think maybe the oil filter bypass is stuck open... |

|

| Author: | 850man [ Fri Aug 02, 2019 11:35 am ] |

| Post subject: | Re: Camshaft and lifter failure |

Its got noting to do with oil flow or oil gallery cleaning The lobes of a A series camshaft are not oil feed, so its a mute point. That cam has failed because its got an agressive ramp profile, was not hardened after grinding, no oil retaining phosphate coating applied. The journal & bearing damage has been caused by all the metal from the cam destroying itself. |

|

| Author: | IndigoBlueCooperS [ Fri Aug 02, 2019 2:40 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

The cam lobes look to be 3/8, or are they 1/2 inch? I would think 3/8 will give higher point loads, and potentially early failure. Only my thoughts, as I have never used 3/8 lobe cams unless in a stock small bore. |

|

| Author: | awdmoke [ Fri Aug 02, 2019 5:12 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

mini-dunger wrote: Has anyone got that diagram of the oil flow path in a. A-series? The engine had something go through it as the bearings had scuff marks in them. like this?

|

|

| Author: | awdmoke [ Fri Aug 02, 2019 5:15 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

Maybe this oil flow diagram is more what you are after?

|

|

| Author: | GR [ Fri Aug 02, 2019 6:55 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

850 man David please don't make silly statements like you have just made, you know nothing about cam design so why would you say that the cam is to aggressive. Maybe you can tell the people on this forum about this cam rate of lift velocity, acceleration, lift per deg and so on, if this cam is to aggressive how come race cams live which are way more aggressive than this cam. Phosphate coating is not necessary on steel camshafts if the Rockwell hardness is there Clive at Clive cams treats his cams, Clive being a good friend of mine, have talked about coatings on cams and if the hardness of the cams and follower are right not a problem. May be you should ask the man what oil he used and what he told me this morning was he used a cheap oil to run it in. The reason the followers have gone like that is poor quality oil or followers to soft or not ground correctly. I with out a doubt grind more mini cams than any one in Australia at the moment I have 25 cams waiting to be ground and they just keep coming in so I must be doing something right. As for oil I recommend GULF WESTERN I have been through the factory to see how they blend their oils and there motto is if there is a better oil on the market they will match it or better it,we run the oil to 230deg F to 9500 RPM in a rotary mazda way beyond the limits of a mineral oil and the bearings were like new when the motor was pulled down.(AND IT'S AUSTRALIAN OWNED) The cams that BMC made varied as production went on the MK 1 S being the best as in steel used and heat treatment used from then on they went down hill as in MK 2 S and then the 1100S, but the A+ cam is an excellent cam to grind it is flame hardened and measures close to 60RC and the hardness is very deep. One thing that you should not do is to wind your motor over and over to try and get oil pressure up, prime the pump and oil ways and fire it up that is the fastest way to get oil to the cam as the cam relies on splash to oil the lobes. Winding the motor over and over rubs all the lube off the lobes, not good. If a good assembly lube is used on the bearings during assembly a motor will run for 5 minutes or more with no oil pressure at low RPM. Graham Russell |

|

| Author: | gtogreen1969 [ Fri Aug 02, 2019 8:22 pm ] |

| Post subject: | Re: Camshaft and lifter failure |

GR wrote: 850 man The only time David contributes to this forum is to try and put down other businesses especially yours.

David please don't make silly statements like you have just made, you know nothing about cam design so why would you say that the cam is to aggressive. Maybe you can tell the people on this forum about this cam rate of lift velocity, acceleration, lift per deg and so on, if this cam is to aggressive how come race cams live which are way more aggressive than this cam. Phosphate coating is not necessary on steel camshafts if the Rockwell hardness is there Clive at Clive cams treats his cams, Clive being a good friend of mine, have talked about coatings on cams and if the hardness of the cams and follower are right not a problem. May be you should ask the man what oil he used and what he told me this morning was he used a cheap oil to run it in. The reason the followers have gone like that is poor quality oil or followers to soft or not ground correctly. I with out a doubt grind more mini cams than any one in Australia at the moment I have 25 cams waiting to be ground and they just keep coming in so I must be doing something right. As for oil I recommend GULF WESTERN I have been through the factory to see how they blend their oils and there motto is if there is a better oil on the market they will match it or better it,we run the oil to 130deg F to 9500 RPM in a rotary mazda way beyond the limits of a mineral oil and the bearings were like new when the motor was pulled down.(AND IT'S AUSTRALIAN OWNED) The cams that BMC made varied as production went on the MK 1 S being the best as in steel used and heat treatment used from then on they went down hill as in MK 2 S and then the 1100S, but the A+ cam is an excellent cam to grind it is flame hardened and measures close to 60RC and the hardness is very deep. One thing that you should not do is to wind your motor over and over to try and get oil pressure up, prime the pump and oil ways and fire it up that is the fastest way to get oil to the cam as the cam relies on splash to oil the lobes. Winding the motor over and over rubs all the lube off the lobes, not good. If a good assembly lube is used on the bearings during assembly a motor will run for 5 minutes or more with no oil pressure at low RPM. Graham Russell |

|

| Page 1 of 4 | All times are UTC + 10 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|